Want to start a yarn dyeing business in the colorful world?

We are here to guide you through the essential steps. With the right knowledge, passion, and understanding of the yarn coloring/dyeing industry, you can turn it into a profitable startup.

With the revival of handicrafts and growing interest in sustainable and eco-friendly products, starting a yarn dyeing business can be profitable.

We’ll discuss essential steps including research, planning, sourcing material, basic yarn dyeing techniques, legal consideration, marketing, branding, selling, etc.

Understand the basics, such as the yarn dying, its types, process, fabric characteristics, dye material, techniques, business models, and ideas to develop your foundational knowledge.

Without further ado, let’s get started.

What is yarn dyeing?

Dyeing yarn is the process of coloring individual yarn strands with many colors and patterns before they are woven or knitted into fabric.

Benefits of yarn dyeing:

- Provides consistent, accurate colors

- Best for creating detailed patterns (stripes and checks)

- Provide better colorfastness and durability

- You can get unique textural effects

- More economical with less waste

- Environmentally friendly with efficient dye use

Yarn dyeing is not a difficult process, it is a fundamental process in the textile industry, for achieving desired hues and shades, yarn is colored in a special process.

Learn (reading the blog post): Yarn dyeing process with steps.

Also, it is the crucial step in the production of colorful fabrics, knitwear, and a different variety of textile products, it enhances the aesthetic appeal and visual diversity of textiles.

Types of yarn dyeing:

There are several types of yarn dyeing techniques are commonly used in the industry.

Some of these include skein dyeing, package dyeing, space dyeing, and yarn painting.

Each technique offers unique characteristics and results in different color distribution patterns on the yarn, here we mentioned some types of dyeing methods, that you can analyze.

- Garment dyeing

- Dip dyeing

- Natural dyeing

- Immersion dyeing

- Bale Dyeing

- Variegated

- Shibori dyeing

- Batik

- Hank yarn dyeing

- Solid dyed yarn

- Tonal

- Beam dyeing

Is starting a yarn dyeing business profitable?

The demand for customized and artisanal textiles has been growing steadily over recent years due to increased interest in handmade goods and personalized products.

By starting a yarn dyeing business, you can tap into this market niche and offer your customers beautifully dyed yarns that cater to their specific preferences.

There are numerous benefits to starting a yarn dyeing business, firstly, it allows you to unleash your creativity by experimenting with different colors and creating unique color combinations.

Additionally, it provides opportunities for collaborations with other artisans such as weavers or knitters who require custom-colored materials for their projects.

Moreover, as an entrepreneur in the textile industry, you have the potential to establish strong relationships with manufacturers or designers who may become long-term clients.

This can lead to steady revenue streams while building your reputation within the industry.

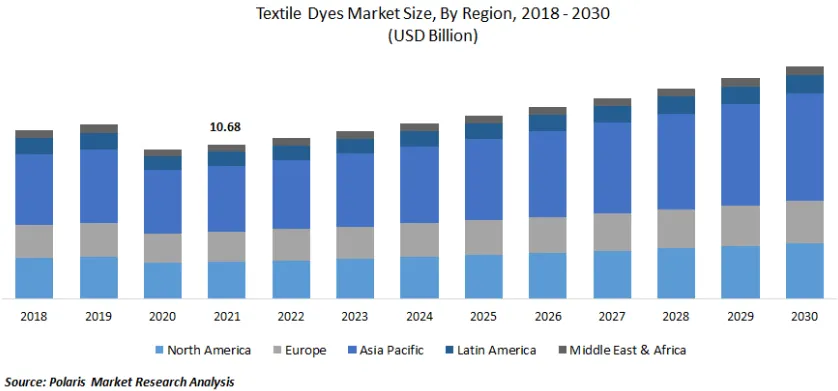

As per a report by (Polaris Market Research Analysis), the global textile dyes market was valued at $10.68 US billion in 2021, and with a 4.7% CAGR growth rate, the market is expected to reach $16.08 billion in 2030.

This data indicates the industrial growth rate of cloth dyes.

For more details, you can visit the official website.

The pros and cons of this business idea:

Pros:

- Be creative

- Niche and customize

- Collaborate (partner with local artisans)

- Online sales (build a strong online presence)

- Eco-friendly line (use natural dyes, promote sustainability)

- Brand building opportunity (unique color stories)

- Good profit margin

Cons (Solutions):

- High startup cost (start small and scale gradually)

- Color consistency – Getting the best color practice is important

- Competition – The market will be competitive with industry growth

- Seasonal sales – still depend on products

- Chemical risks (use safety equipment and ventilation)

- Inventory management problem (made-to-order + pre-dyed stock)

- Market trends fluctuations

How to start a yarn dyeing business – steps guide

1. Research the market

Before getting started, understand and identify your target market.

Research is important to target a specific market segment, according to market demand, competition, and customer preferences.

- Identify your niche: Determine what type of yarn dyeing you want to focus on (e.g., natural dyes, synthetic dyes, specific fiber types).

- Understand your target market: Research potential customers including- crafters, knitters, weavers, and textile manufacturers.

- Analyze competition: Study existing yarn dyeing businesses to identify gaps and opportunities in the market.

Gather Information about the market as much as possible, conduct surveys, focus on groups, research online, and analyze the industry to get relevant data.

An in-depth analysis of market demand, competition, and your competitors can help to establish a business or grow in the competitive market.

2. Develop a yarn dyeing business plan

After conducting market research and competitive analysis, the next step is to develop a strategic plan for your dyeing business.

Having a written plan can help outline your goals, strategies, and targets, which will contribute to the creation of a successful business.

Here are some important points to consider:

- Executive Summary: This is the primary step of business planning, write an overview of your business goals and vision, and what you hope to achieve by starting.

- Company Description: Write basic information about your company’s history, business setup, ownership structure, and location.

- Products and Services: Describe the types of yarn you will dye and any other products/services you will provide (e.g. kits, equipment, classes).

- Market Analysis: Research the hand-dyed yarn market, your competitors, customer preferences, market pricing, demand, etc.

- Operations Plan: Write details on your dyeing process, suppliers, production capacity, quality control, team management, inventory, selling, marketing, etc.

- Marketing Plan: Outline how you will promote your business and attract customers, through various marketing strategies, etc.).

Financial planning is a vital part of your business plan, how you will set your budget and going to manage the finances.

Don’t make the plan complicated, just understand the basics and write the necessary steps.

When building a plan for your yarn dying line, use online business plan templates to simplify the process, you can cover essential sections by following that guide.

3. Setting up your business

Once your business plan is ready, the next step is setting up your yarn dyeing facility, which requires careful consideration, location selection, equipment, and supplies.

Suitable location for the dyeing unit:

Choose a suitable location that meets the specific requirements of the facility, such as access to water supply, electricity, transportation, proper ventilation, and rental costs.

Follow when selecting a location:

- Zoning: Check the location facility for industrial or manufacturing, and also follow the zoning regulations.

- Water and electricity: There should be adequate water and electricity supply.

- Wastewater: The location must facilitate a system for handling wastewater.

- Raw material: Suppliers of raw materials close to your target location.

- Should be an easy to accessible area for customers.

- Cost: Check the rental cost of this location.

- Size of the business: Calculate, how much space is needed.

Once the location is finalized, then plan to set up the workspace. The process includes: designing and organizing the layout of dyeing vats, drying racks, and storage areas.

Acquire necessary equipment and machinery:

For efficient operation, having the right supplies, equipment, and machinery is important, including dyeing machines, steamers, temperature control systems, skeins, etc.

Before gathering those supplies learn the process of dying, then create a list of the essential supplies, that are needed in this project.

- Stainless steel pot

- Yarn cones or skeins

- Dyeing chemicals

- Water supply

- Heat source (steam boiler)

- Mixing tanks

- pH meters

- Drying racks

- Weighing scales

- Safety equipment (gloves, masks, etc.)

When purchasing must consult with a textile dyeing professional, who can help you choose the suitable equipment, supplies, and chemicals, for your specific budget and needs.

- Yarn (natural or synthetic fibers)

- Dyes (acid, direct, reactive, etc.)

- Chemicals (alkalis, acids, leveling agents, etc.)

- Water (used in the dyeing process)

- Auxiliaries (wetting agents, dispersants, etc.)

4. Learn the yarn dyeing process

Move towards the yarn dyeing process and technique.

Quality of raw materials can directly impact the outcome of the dyeing process, so the point is, to always choose high-quality material.

Yarn dyeing methods:

There are many ways to dye or customize yarn, depending on requirements (DIY or commercial), the methods can be different, some allow dyeing in bulk, and some methods are manual for DIY.

DIY dyeing:

Focus: Smaller projects, experiments, and creative effects.

Methods:

- Simple method: Skein and pot dyeing (both similar)

- Other: Acid dyeing, Natural dyeing, Solar dyeing, Shibori dyeing, Tie-dyeing.

Commercial dyeing:

- Focus: Large-scale production, consistent color, efficiency.

- Methods: Package dyeing, Warp beam dyeing, Jet dyeing, etc.

Each dyeing process has its advantages, depending on the type of yarn, the quantity of production, and the desired color effects.

To achieve consistent and high-quality results, learning the dyeing process, its basic information, and its material is important for you.

Practice makes you perfect.

Learn the yarn dyeing process:

Yarn dyeing is a complex and multi-step process, as well as time-consuming, that is why first you have to learn the proper technique.

In short, the steps are:

- Prepare yarn on carriers.

- Clean the yarn (scouring).

- Immerse yarn in the dye bath.

- Rinse to remove excess dye.

- Dry the yarn.

- Apply finishing treatments.

- Inspect for quality.

You can learn the yarn dyeing process by reading blogs, joining training programs, learning from online YouTube videos, and exploring various visual content.

5. Legal and regulatory compliance

Your business should comply with necessary legal requirements, as per your local, state, country, and industrial regulations.

The first step is to set up the appropriate legal structure for your business, such as a sole proprietorship or limited liability company.

Choose a legal structure: Each has its advantages and considerations.

- Small and simple: Sole Proprietorship (easy setup, full liability)

- Growing but moderate risk: LLC (protects personal assets, pass-through taxes)

- Large with high risk: Corporation (strongest protection, complex setup, double tax)

Must register your business with relevant authorities and comply with its tax regulations, the registration process and fees can differ from state to state.

Acquire necessary licenses and permits to run your business smoothly, research industry-specific legal documents, and fulfill as required.

Other steps:

- Obtain insurance which coverage protects your business from unforeseen events.

- Opening a dedicated business bank account helps maintain financial transparency and separation of personal and business funds.

Consult a legal advisor or attorney to get more practical advice.

6. Branding and marketing

The yarn dyeing industry is competitive and demanding also, to make a profit by starting a yarn dyeing business, it is important to have a good marketing strategy.

With effective marketing ideas, you can build connections and relationships with suppliers, wholesalers, buyers, textile manufacturers, crafting enthusiasts, and artists.

Identify the target customer base, implement your marketing efforts, and increase your sales.

Why are branding and marketing important?

- To differentiate from the competition

- Marketing to attract new customers

- You can build loyalty among existing customers

- Branding helps to increase your sales

Don’t forget the power of digital marketing and social media. Create content (blog posts, YouTube tutorials, reels, social media posts) to increase the online presence.

For bulk selling and getting bulk yarn dyeing orders, connect directly with buyers.

Launching a yarn dyeing business requires proper research, planning, and resources. Your dedication, hard work, learning, and patience, are also crucial for success.

Hopefully, the guide is helpful and informative, if there are any doubts comment to us.

Related post:

Frequently Asked Questions (FAQs)

So let us discuss some frequently asked questions regarding the yarn dyeing business.

Can you make money selling yarn?

Yes, you can make money selling yarn, but it takes strategy. By focusing on high-quality, unique yarns with beautiful color combinations and textures, you can attract both wholesale buyers and individual crafters.

Is it difficult to dye yarn?

Dyeing yarn can be like cooking – easy for basic colors on natural fibers, but trickier for fancy effects or synthetics. Beginners can learn online and in craft stores to get started with basics.

What is the disadvantage of yarn dyeing?

Yarn dyeing does not have any specific disadvantages, however time-consuming, labor-intensive, messy, expensive, time-management, and wastage (if the color is not consistent).

What is the best dye for yarn?

No single “best” dye, you can select based on your yarn:

Acid Dyes: For protein fibers; vibrant and colorfast.

Fiber Reactive Dyes: For plant fibers; permanent and bright.

Natural Dyes: Eco-friendly for all natural fibers; unique tones.

Vat Dyes: For cellulosic fibers; deep, rich colors.